The parts that form the backbone of the engine are formed using casting technology, in which molten metal is poured into a mold to form a shape, and forging technology, in which hot iron is beaten into shape.

Casting is a metalworking technique in which a mold is used to form the shape of the product. Compared to the cutting method, in which tools are used to cut the metal, casting can form complex shapes more easily, and is therefore widely used in the manufacture of engine parts, tire wheels, and other products.

Forging is a manufacturing process of forming metal by striking. Forging is used in the production of crankshafts and connecting rods for automotive parts.

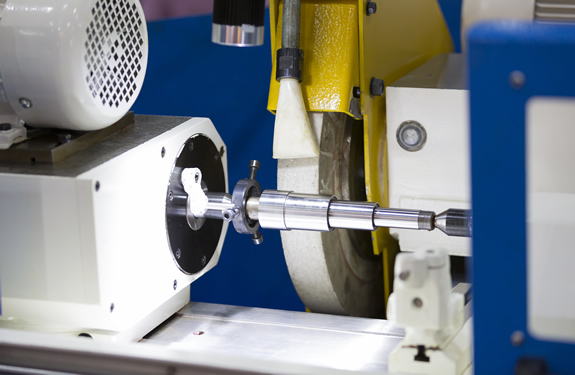

Materials obtained through casting and forging processes are polished to micron precision. Because the materials are directly related to the power, safety, and reliability of automobiles, the demand for quality is extremely rigorous. Our highly-skilled engineers provide the knowledge necessary to achieve this level of quality.