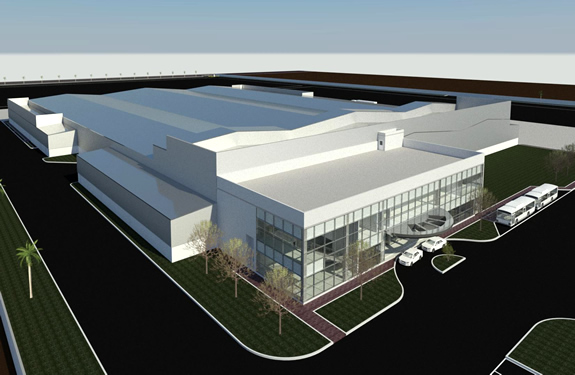

Our strength is our ability to provide one-stop support for the construction of automotive plants with a wide variety of facilities, including welding, painting, assembly, inspection, casting, processing, and development facilities. From site acquisition to building and process design, construction, equipment installation, trial operation, and maintenance and operation, ICE can handle all of the necessary aspects in making your product a reality.

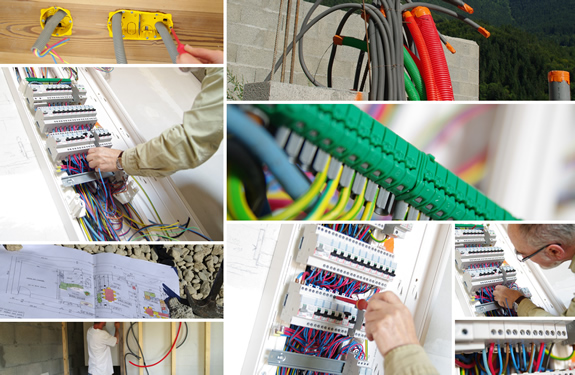

Our services are not limited to new plant construction, but also include renovation and expansion, seismic diagnosis and reinforcement, renewal of electrical and mechanical equipment, and energy conservation.

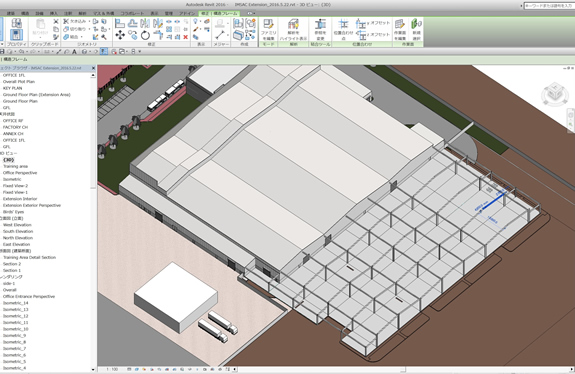

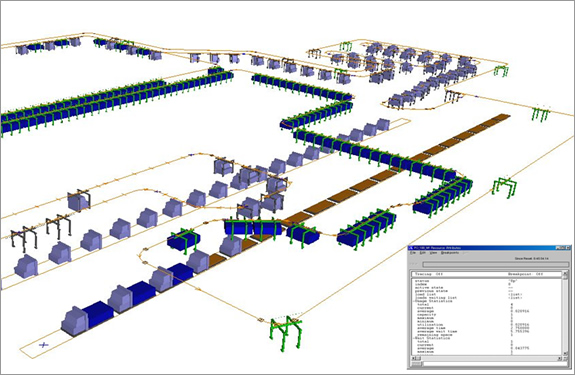

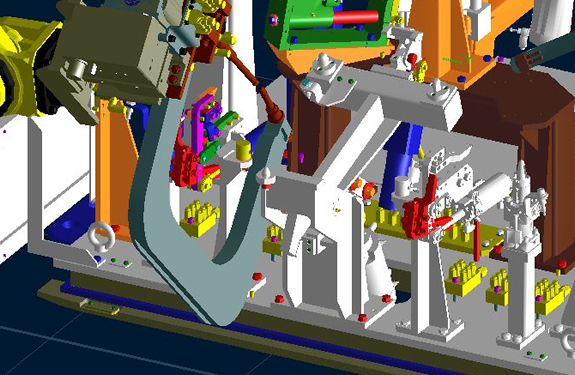

In the automotive industry, which is becoming increasingly virtual, ICE constantly aims to incorporate new technologies. Digital engineering tools are an essential part of ICE, such as visualizing equipment verification and production capacity simulation, as well as production management systems for production forecasting and preventive maintenance.

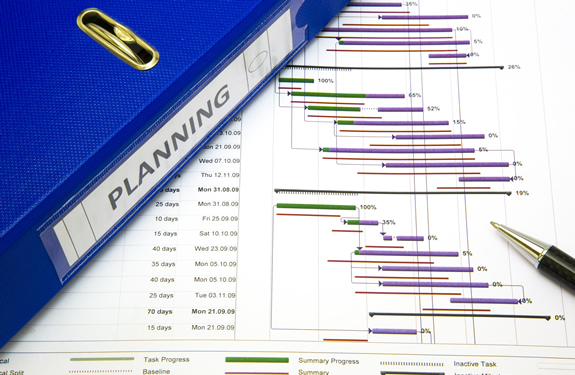

Even with the development of equipment and tools, human work is always necessary. The method of promoting work while strictly monitoring quality, cost, and deadlines is called project management. Planning & Mobility is required to plan and carry out projects.